Aluminum Die-Casting

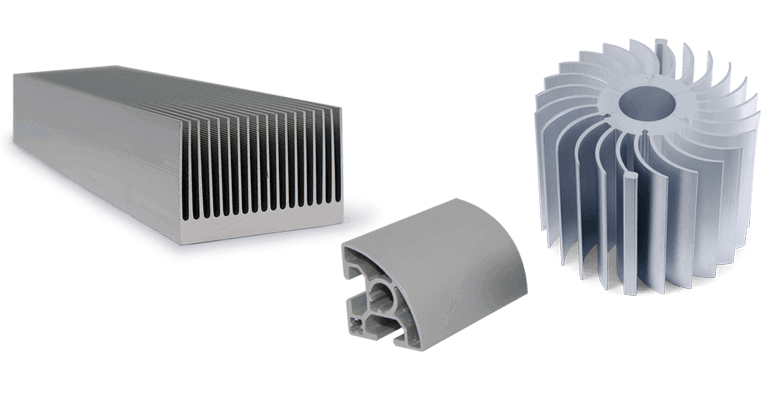

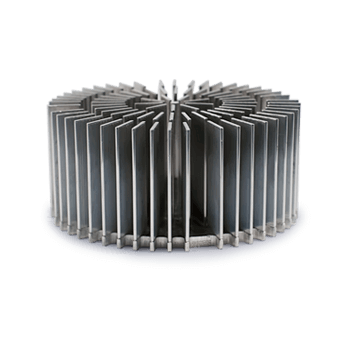

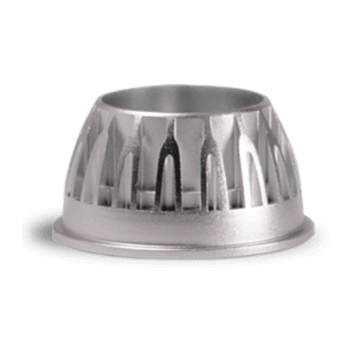

Aluminum die-castings are available in alloys including A380 and A383. Features of aluminum die-castings include thin wall, corrosion resistance, light weight, nice surface, and electrical conductivity.

Die casting utilizes 1 to 800 ton cold chambers with manual & automated operations. We have supplied aluminum die casting parts and enclosures to aerospace, military, electronic, medical markets.

Why use our Al die-casting products?

Thin wall

Thin wall Corrosion resistance

Corrosion resistance Light weight

Light weight Nice surface

Nice surface Electrical conductivity

Electrical conductivity