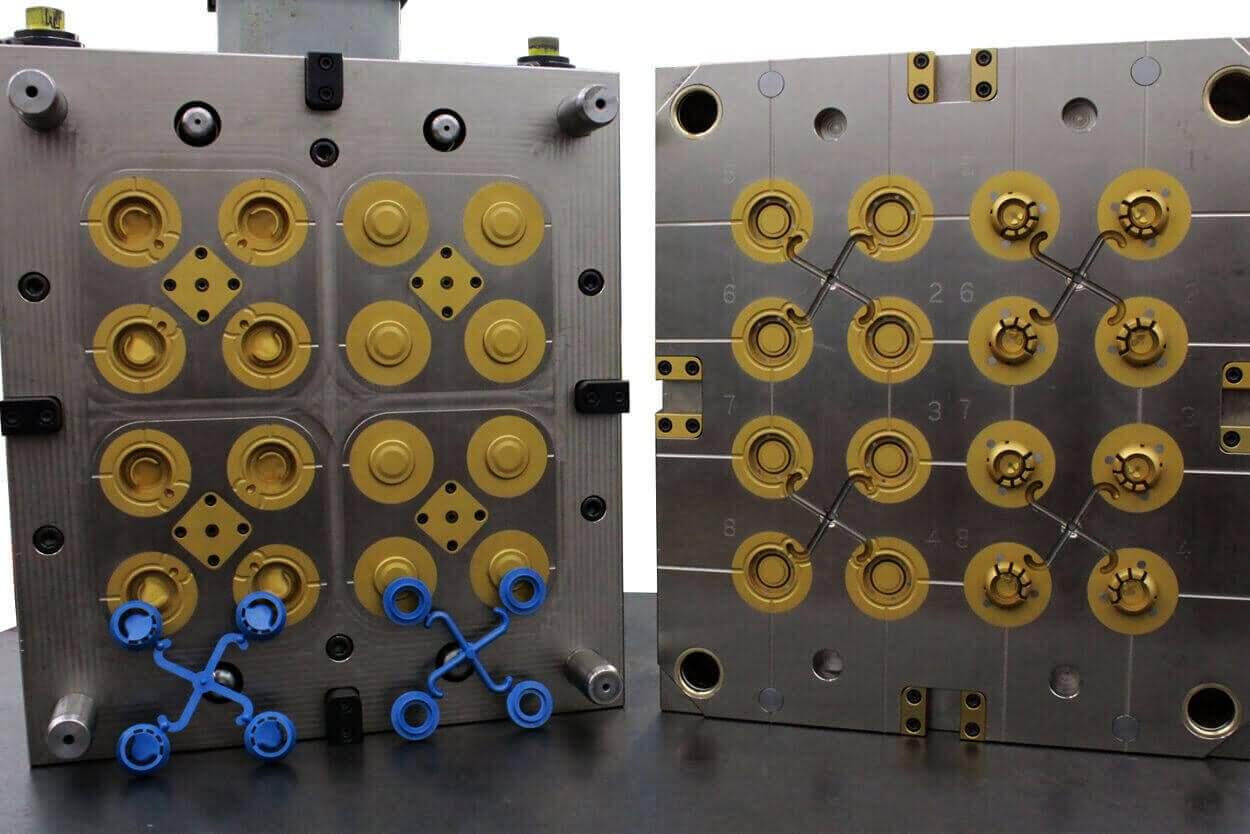

Let our custom injection molding engineers help you design the injection molded parts you need. We specialize in tough custom molding jobs where the design, choice of plastic, mold building and flow analysis are critical to production.

We are checking:

Fill time

Air traps

Confidence of fill

Flow front temperature

Injection pressure

Pressure drop

Quality prediction

Solid model

Weld lines