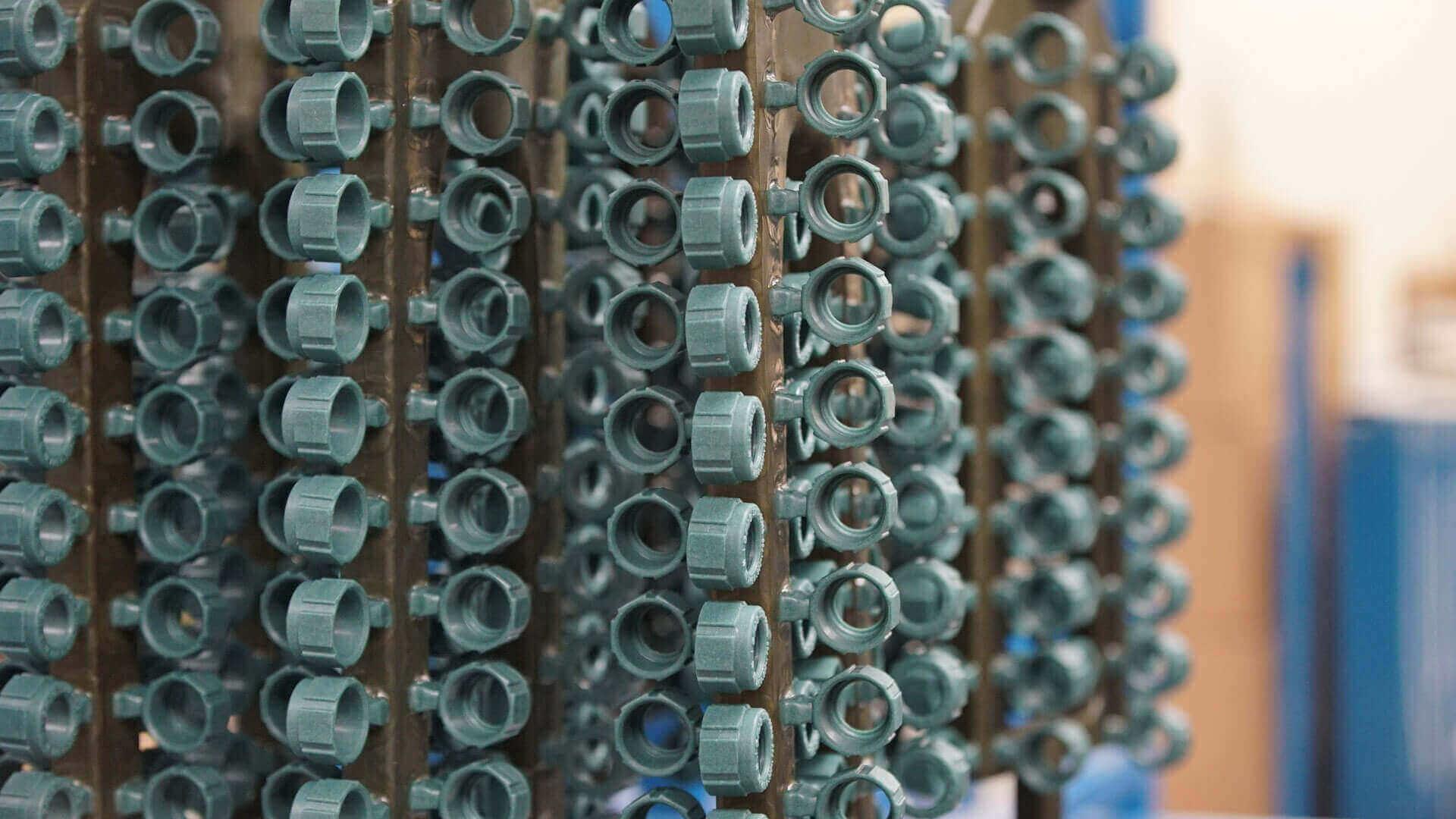

Sodium Silicate Investment Casting

1. The coasting bond brushed on the pattern surface is water glass in this process.

2. Compared with the sand castings, parts made with lost wax casting(water glass) have better surface quality (surface roughness to 12.5 microns) and higher dimensional accuracy.

Silica Sol Investment Casting

1. The coasting bond brushed on the pattern surface is silica sol in this process.

2. Parts made with lost wax casting(silica sol) have the tolerances are 0.1 mm for the first 25 mm (0.005 in for the first inch) and 0.02 mm for the each additional centimeter (0.002 in for each additional inch).

3. A standard surface finish is 1.3 – 4 microns (50 –125 μm). Compared with the water glass process, parts made with lost wax casting(silica sol) have excellent surface finish and higher dimensional accuracy.

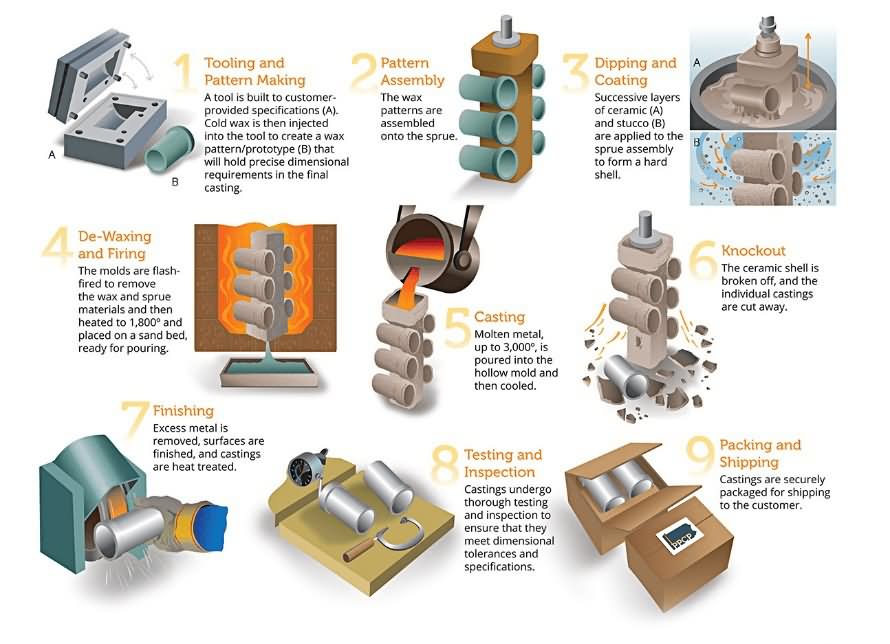

The Process of Investment Casting

Main Steps:

1.Produce a master pattern

2.Create a mold

3.Produce wax patterns

4.Assemble wax patterns

5.Apply investment materials

6.Dewaxing

7.Pouring

8.Divesting

(The detail picture is showing on the right.)

The Advantages of Lost Wax Casting

Excellent surface finish

High dimensional accuracy

Extremely intricate parts are cast able

Almost any metal can be cast