Metal Stamping in China

We are an American owned manufacturing company in China with strong capabilities in:

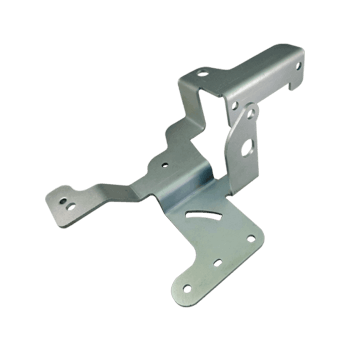

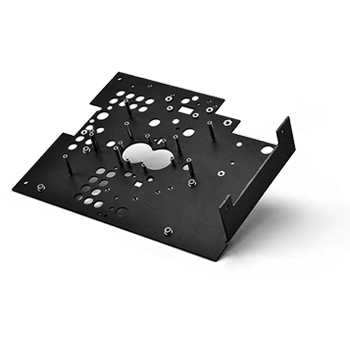

Normal stamping (Blanking, Bending, Forming, Piercing, Coining…)

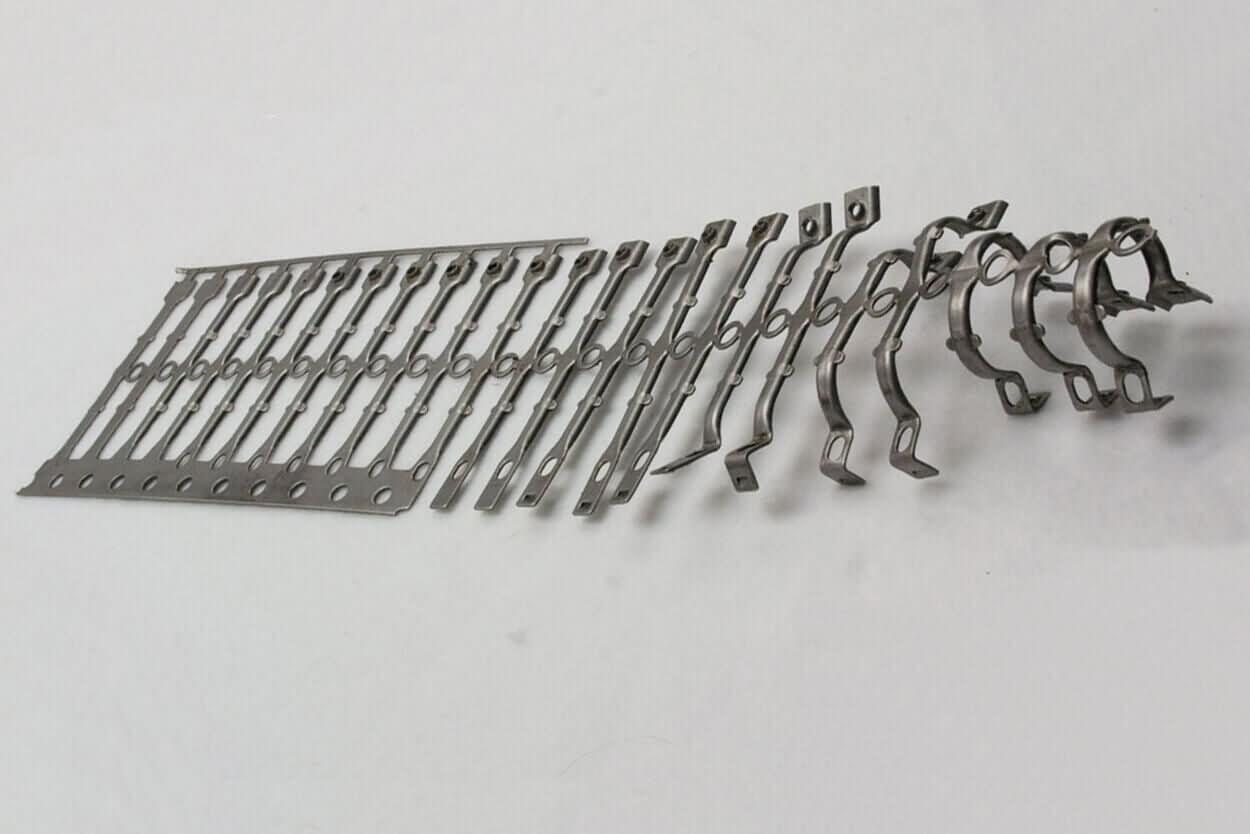

Normal stamping (Blanking, Bending, Forming, Piercing, Coining…) Progressive die- / high-speed stamping

Progressive die- / high-speed stamping Robot stamping

Robot stamping

From low to high quantity items we are your preferred manufacturer for stamping products. We provide all secondary finishing processes such as welding, bending and surface treatment like powder coating and anodizing