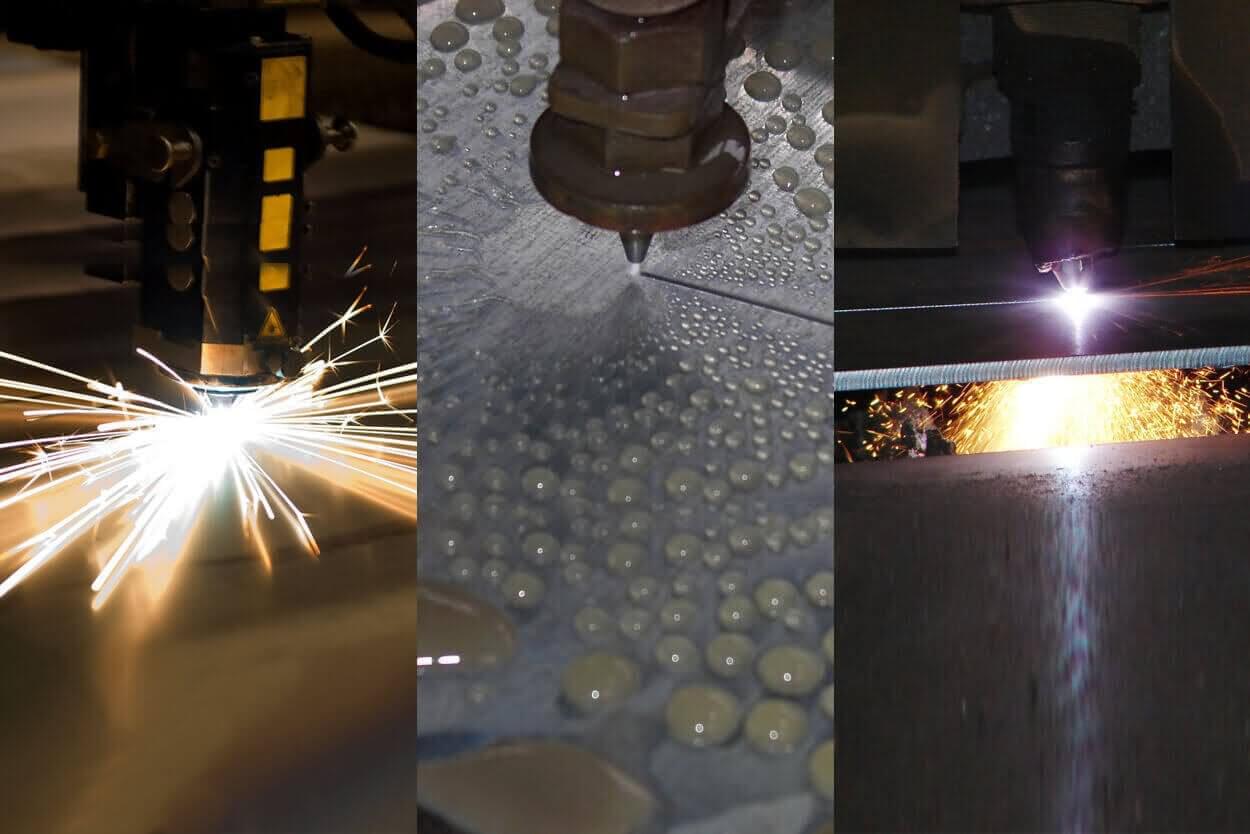

Using different technology such as waterjet, laser or plasma cutting - each way of cutting with advantages and disadvantages

Waterjet cutting

Compare to plasma and laser cutting, the waterjet cutting has no material deformation, no head affected zones and therefore no hardening or changes to the metal structure. Water jets can typically cut most 3-dimensional objects.

It is a cold cutting process and cut thickness up to 12”/305mm. The cut edge quality usually is good and machines are less expensive. Waterjet machines are one of the most versatile cutting processes around and is well suited also for high performance titanium cutting.

Laser Cutting

A laser cutter on the other hand, uses a CO2 (or Nd, Nd-YAG) gas as power source for laser energy, creating a rapid heating process that melts or vaporizes material. Laser cutting machines can typically cut not more than 1″/25mm and the edge usually requires re-working. It causes material hardening and burr formation but the tightest tolerances are 0.002”/0.05mm. The energy consumption is less compared with plasma cutting.

Plasma cutting

A plasma cutting system has a cutting torch, through which concentrated electrical currents and high velocity gas flow. Intense heat is created, which cuts the metal and causes hardening and burr formation. Plasma cutting machines are capable to cut more levels of detail but only cut metal. It can cut more thicker sheet metal , up to 3”/76mm, than laser cutter and you need wear protective gear because the plasma emits radiation.

So which is better?

There is no one machine that is better than the others. Depending on the application, a laser or high profile plasma cutter may be right for the job. That’s why it’s important to work with a company that has the latest technologies and best machines available. This will not only ensure higher quality and greater detail in the finished product, but a speedier turnaround and more reliable results. No one can really truthfully say which of these are better, solely because it just depends on the project you’re working on and the material you are using. Should you need help deciding how to choose, we are just a click away.

If thicker materials need to be cut, we also offer flame cutting capacity. Flame cutting only works with carbon steel. Material thickness from 0.2”/5mm up to 16”/406mm, the precision is around 1 mm.

Some samples from our work for cutting