Clean room environment for food-grade

Clean room environment for food-grade Small-quantity

Small-quantity Prototype products

Prototype products

Plastic Manufacturing Process

Over the years, we have built capacities to manufacture a variety of products:

Very large products

Very large products Products with cosmetic features

Products with cosmetic features Precision products at very tight tolerance

Precision products at very tight tolerance

Plastic Injection Mold Design

Let our custom injection molding engineers help you design the injection molded parts you need. We specialize in tough custom molding jobs where the design, choice of plastic, mold building and flow analysis are critical to production.

| Common plastics and use | ||

| PES | Polyester | Fibers, textiles |

| PET | Polyethylene terephthalate | Carbonated drinks bottles, peanut butter jars, plastic film, microwavable packaging |

| PE | Polyethylen | Wide range of inexpensive uses including supermarket bags, plastic bottles |

| HDPE | High-density polyethylene | Detergent bottles, milk jugs, and molded plastic cases |

| PVC | Polyvinyl chloride | Plumbing pipes and guttering, shower curtains, window frames, flooring |

| PVDC | Polyvinylidene chloride | Food packaging, such as Saran |

| LDPE | Low-density polyethylene< | Outdoor furniture, siding, floor tiles, shower curtains, clamshell packaging |

| PP | Polypropylene | Bottle caps, drinking straws, yogurt containers, appliances, car fenders (bumpers), plastic pressure pipe systems |

| PS | Polystyrene | Foam peanuts, food containers, plastic tableware, disposable cups, plates, cutlery, compact-disc (CD) and cassette boxes |

| HIPS | High impact polystyrene | Refrigerator liners, food packaging, vending cups |

| PA | Polyamides, nylons | Fibers, toothbrush bristles, tubing, fishing line, low-strength machine parts such as engine parts or gun frames |

| ABS | Acrylonitrile butadiene styrene | Electronic equipment cases (e.g. computer monitors, printers, keyboards), drainage pipe |

| PE/ABS | Polyethylene/Acrylonitrile Butadiene Styrene | A slippery blend of PE and ABS used in low-duty dry bearings |

| PC | Polycarbonate | Compact discs, eyeglasses, riot shields, security windows, traffic lights, lenses |

| PC/ABS | Polycarbonate/Acrylonitrile Butadiene Styrene | A blend of PC and ABS that creates a stronger plastic used in car interior and exterior parts, and mobile phone bodies |

| PU | Polyurethanes | Cushioning foams, thermal insulation foams, surface coatings, printing rollers (Currently sixth or seventh most commonly used plastic material, for instance the most commonly used plastic in cars. |

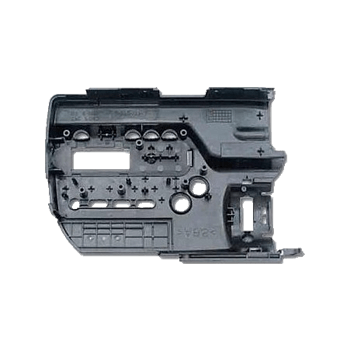

Example of parts made for OEM projects:

Why working with us on your plastic-injection project?

We assist our clients to refine their product design and assure the product’s accuracy, quality and competitiveness according to the customers’ specifications.

One stop solution for all your plastic products with all manufacturer possibilities inclusive prototyping, mold design and mass production.

We execute our tooling in-house; Our mold-processing department is equipped with state of the art CNC machineries and produce more than 50 molds every month.