Mandrel Drawing for DOM Pipes

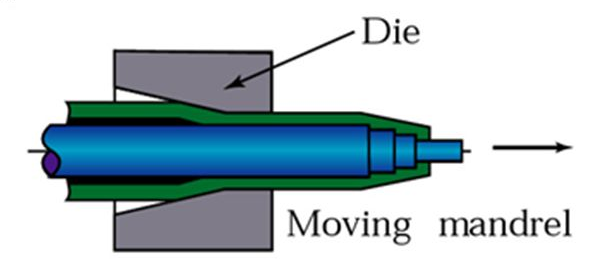

Manufacturing Process: In this process, the tube is first cleaned (entire flash weld is removed) and annealed, and one end is squeezed to a point so it can be gripped by the drawing mechanism. The tube is then drawn through one or more dies and over mandrels. This reduces the diameter of the tube and thins its walls to the required dimensions in a controlled fashion。

Benefits: better dimensional tolerances, improved surface finish,improved tensile strength, increased hardness and good machinability. DOM is sometimes incorrectly referenced as “seamless tube” when it actually does have a seam (almost invisible).

to provide the qualities desired in the finished product. Metallurgically, drawing improves the tube’s concentricity, tensile strength, hardness and machinability. Close dimensional accuracy is achieved through tight control of both outside and inside diameters.